Images below document the step by step process of creating the sustainable notebooks, from trimming the collected paper to binding the individual booklets.

COLLECTED PAPER

The image below displays the range of waste paper stocks that were collected throughout the first five months on the course.

The stock, which will form the covers and interior pages of the notebooks, was collected from bins and tables from around the university, and so would have otherwise been sent to be recycled. By collecting and using waste paper stock instead of buying some recycled stock from the internet I am able to vastly reduce the carbon footprint associated with the notebooks.

CARBON REDUCTION -

- Saves the energy associated with sorting, transporting and recycling the waste paper.

- Saves having to buy new recycled stock for the notebooks helping to avoid the energy use associated with making and transporting the recycled paper.

|

| Stock collected over a four month period. |

|

| I also collected some recycled grey board for the notebook covers that had previously been used to print business cards. Luckily for me, the board was unused due to a misprint. |

TRIMMING

The stock that was collected came from a range of sources and undoubtedly had been used for a range of purposes. A consequence of using waste paper was the varying sizes of the individual sheets. One of the first major tasks that needed completing as part of the project was the process of trimming all the sheets down to the same size.

|

| Paper was trimmed using the guillotine. |

|

| Paper was trimmed to an A4 size so that when folded it met the outlined individual page size of A5. |

NOTEBOOK PRODUCTION

The sheets of trimmed paper were taken back to my house where I completed the various stages of the binding process.

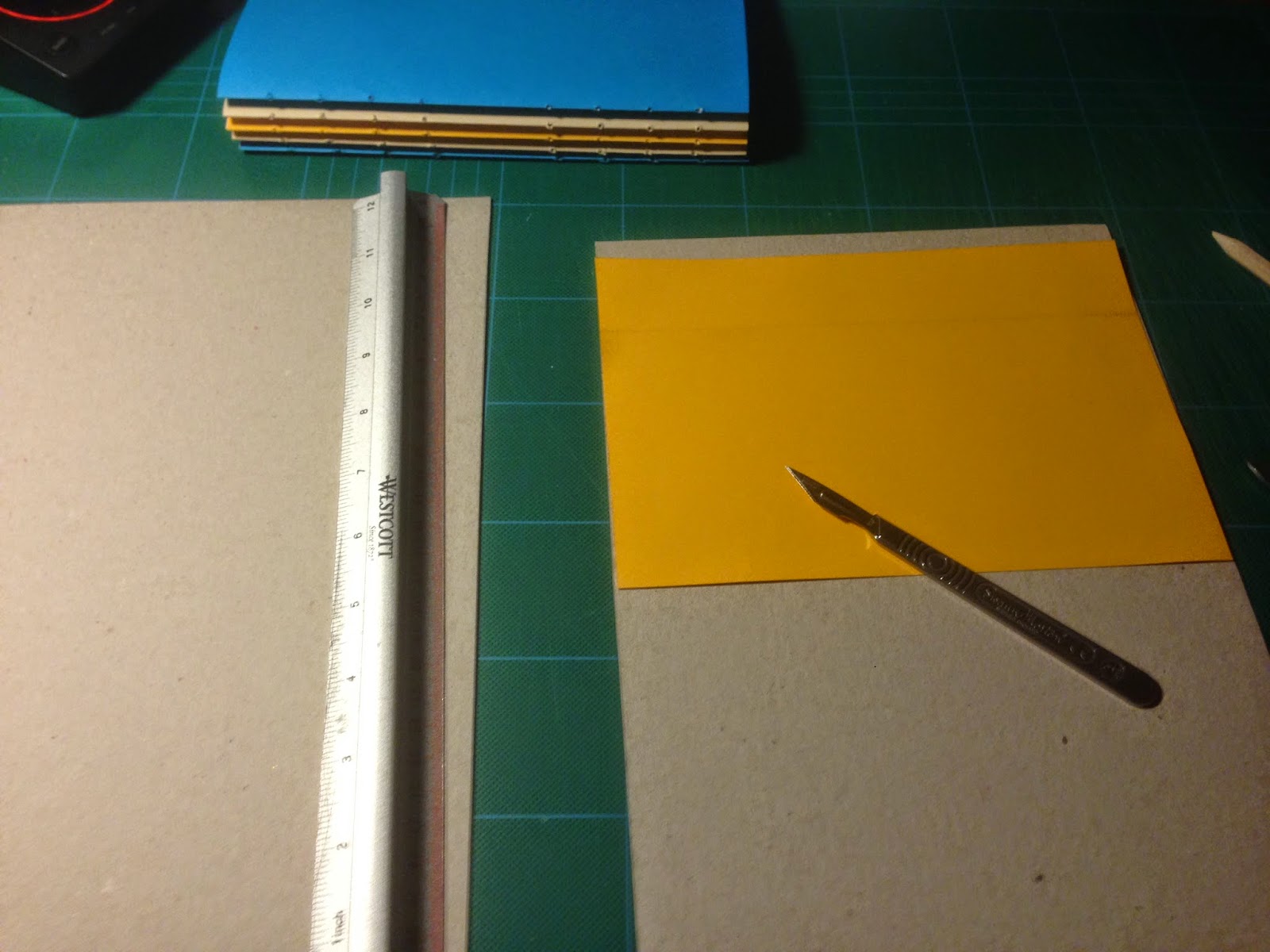

|

| Tools used during the binding process. |

|

| Folding the paper was very tedious and took over three hours. |

|

| Paper was arranged into piles of stock type, this helped when creating the individual signatures. |

|

| The signatures consisted of six folded pages and varied in stock type giving the books a lot of character. |

|

| An etching needle and custom template were used to pierce holes through each signature. |

|

| Each booklet will feature five signatures giving a total of 120 individual pages. |

|

| The coptic stitch was completed using hemp string, a stronger and more sustainable alternative to most conventional twines. |

FINISHED NOTEBOOKS

After the stitching process was completed the notebooks had any excess trimmed from the pages and covers to ensure that they are neat and finished to a professional standard.

Once the process of trimming was complete the sustainable notebooks were ready for photographing and sale.

No comments:

Post a Comment